Improved Project Efficiency

Streamline workflows, eliminate waste, and deliver projects more efficiently through proactive clash detection.

Construction industry studies consistently show that up to 30% of project costs are consumed by waste, rework, and inefficient processes. Much of this waste stems from coordination issues that could have been prevented with effective clash detection.

Our clash detection services target these inefficiencies at their source, creating more streamlined workflows that reduce waste, minimize delays, and allow your team to focus on value-adding activities rather than problem-solving in the field.

Common Project Efficiency Drains

Without proactive clash detection, projects often suffer from these efficiency-killing issues:

- Rework Cycles - Installing, removing, and reinstalling systems due to spatial conflicts discovered during construction.

- Work Stoppages - Construction delays while teams determine how to resolve unexpected clashes found in the field.

- Administrative Overhead - Processing change orders, RFIs, and documenting field-discovered issues.

- Material Waste - Ordering, fabricating, and then scrapping materials that don't fit due to coordination issues.

- Labor Inefficiency - Skilled workers standing idle while waiting for clash resolutions or performing low-value rework.

- Management Distraction - Project leaders spending time on reactive problem-solving rather than proactive project optimization.

How Clash Detection Improves Efficiency

Accelerated Construction

By resolving spatial conflicts before construction begins, work can proceed continuously without the stops and starts caused by on-site clash discovery. Projects using thorough clash detection typically see 15-20% faster overall construction durations.

Reduced RFIs

Clash detection dramatically reduces the number of coordination-related Requests for Information during construction. Projects using our services typically see 50-75% fewer RFIs, freeing up management resources for more productive activities.

Optimized Installation Sequencing

Through clash detection coordination, installation sequences can be planned to minimize trade interference and maximize workspace efficiency. This reduces downtime and enables more effective resource allocation.

Streamlined Prefabrication

Well-coordinated models support off-site prefabrication of building components, which can reduce on-site labor by up to 25% and decrease installation time by 20-30% for complex systems.

Our Efficiency-Focused Approach

Process Mapping

We analyze your current project workflows to identify coordination bottlenecks and inefficiency points that can be addressed through clash detection.

Strategic Detection Planning

We prioritize clash detection activities based on their potential impact on project efficiency, focusing resources where they'll deliver the greatest benefits.

Streamlined Resolution Workflows

We implement efficient processes for addressing identified clashes, with clear workflows that minimize response times and administrative overhead.

Sequencing Optimization

We analyze clash-free models to identify opportunities for installation sequence optimization that can further enhance construction efficiency.

Continuous Improvement

We monitor and measure efficiency gains throughout the project, implementing refinements to further optimize the coordination process.

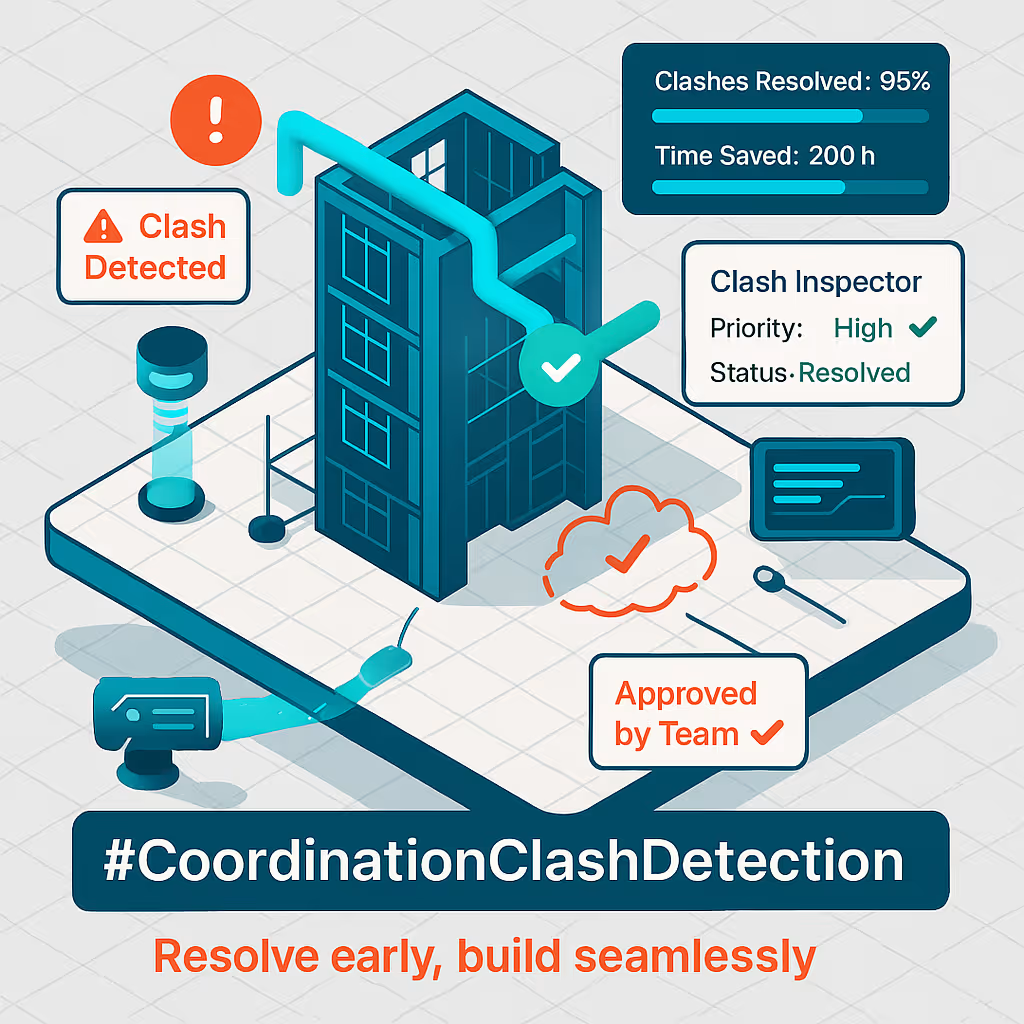

Measurable Efficiency Improvements

Our clash detection services deliver quantifiable efficiency gains:

Schedule Reduction

Projects using our comprehensive clash detection typically see 15-25% shorter construction durations compared to similar projects without proper coordination.

Labor Cost Savings

By eliminating rework and work stoppages due to clashes, projects can achieve 5-8% savings in overall labor costs through improved productivity.

RFI Reduction

Coordination-related RFIs can be reduced by up to 70%, decreasing administrative overhead and accelerating decision-making processes.

Prefabrication Increase

Well-coordinated models enable 30-40% more prefabrication opportunities, shifting work to more controlled and efficient off-site environments.

Efficiency Success Story

Commercial Office Tower

A 45-story commercial office tower with complex mechanical systems and a tight construction schedule faced significant efficiency challenges. The project team engaged our services to maximize construction productivity and meet their aggressive timeline.

Our clash detection-driven approach delivered impressive efficiency improvements:

- Identified and resolved 1,100+ significant clashes before construction began

- Enabled prefabrication of 60% of MEP systems through comprehensive coordination

- Created clear installation sequence plans based on the conflict-free model

- Streamlined RFI processes for any remaining coordination questions

The resulting efficiency gains were substantial:

- Overall construction schedule reduced by 4.5 months (18% improvement)

- MEP installation productivity increased by 32% compared to the client's previous similar project

- Coordination-related RFIs reduced by 78%

- Trade contractor efficiency improved through more predictable workflows

- Project management team able to focus on value-adding activities rather than conflict resolution

The project director commented: "The efficiency gains from clash detection allowed us to complete a 24-month project in under 20 months, delivering significant occupancy benefits to our client."

Related Services

Ready to Build More Efficiently?

Eliminate the waste and delays caused by on-site coordination issues. Contact us to discuss how our clash detection services can streamline your construction process and improve project efficiency.