Error Reduction

Identify and eliminate errors before they impact your project's timeline, budget, and quality.

Reducing errors in design and construction is a primary advantage of working in a coordinated BIM environment. Our approach ensures that inconsistencies and risks are identified early, reducing costly mistakes downstream.

When transforming point cloud data into BIM models, precision and accuracy are paramount. Our rigorous quality control processes ensure that the resulting models faithfully represent real-world conditions while eliminating potential errors and conflicts before they impact construction.

How We Do It

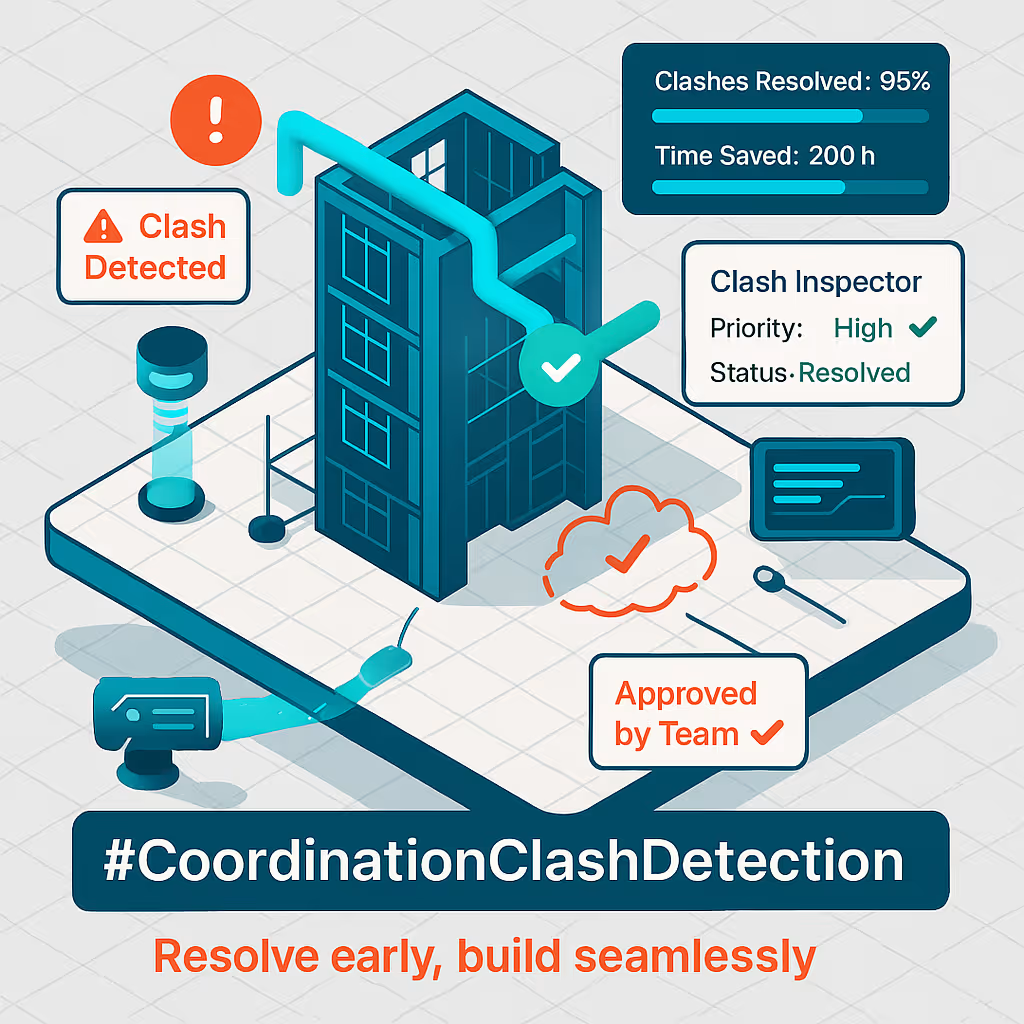

- Clash Detection & Model Validation - We conduct comprehensive clash detection and model validation at key project stages to identify spatial conflicts and inconsistencies.

- Standardized Protocols - We enforce standardized modeling protocols to eliminate ambiguity and ensure consistency across all project elements.

- QA/QC Workflows - We apply rigorous quality assurance and quality control workflows using specialized tools like Navisworks and Solibri to identify and resolve issues.

- Data Consistency - We maintain data consistency across models to support clear documentation and asset tracking throughout the project lifecycle.

Our Quality Assurance Process

Point Cloud Validation

Before modeling begins, we validate point cloud data for completeness and accuracy, ensuring it provides a solid foundation for the BIM model.

Modeling Quality Control

During the modeling process, we apply strict quality control measures to ensure accuracy in geometric representation and element classification.

Interference Checking

We perform systematic clash detection to identify and resolve geometric conflicts between different building systems and components.

Documentation Validation

We validate all documentation generated from the BIM model to ensure it accurately reflects the modeled information and meets project requirements.

Error Prevention Timeline

Our comprehensive approach identifies and resolves errors at every stage of the project:

Planning & Setup

Potential Errors

- Incomplete scan coverage

- Poor scan registration

- Inconsistent modeling standards

Our Prevention

- Comprehensive scanning plans

- Registration accuracy validation

- Clear BIM execution plans

Modeling Process

Potential Errors

- Geometric inaccuracies

- Element misclassification

- Missing components

Our Prevention

- Regular deviation checks against point cloud

- Automated element classification validation

- Comprehensive QA checklists

Coordination Phase

Potential Errors

- System clashes and interferences

- Access and clearance issues

- Discipline coordination gaps

Our Prevention

- Systematic clash detection protocols

- Clearance and accessibility verification

- Interdisciplinary coordination reviews

Documentation & Delivery

Potential Errors

- Documentation inconsistencies

- Data loss during export

- Non-compliant deliverables

Our Prevention

- Systematic documentation review

- Export validation procedures

- Compliance verification against standards

Why It Matters

Fewer RFIs and Change Orders

By identifying and resolving issues before construction, we drastically reduce the number of requests for information and costly change orders during the building phase.

Greater Design Integrity

Our error reduction processes ensure greater design integrity and compliance with all applicable codes, standards, and project requirements.

Better Coordination

Proactive error identification enables better coordination between project partners, creating a more collaborative and efficient project environment.

Predictable Outcomes

Comprehensive error reduction leads to more predictable project timelines and budgets, allowing for better planning and resource allocation.

Error Reduction in Action: Hospital Retrofit Project

A complex hospital retrofit project required precise capture of existing conditions and careful coordination of new MEP systems. Our error reduction approach delivered significant results:

Compared to previous similar projects

Before construction documentation

From early error identification

"The quality control processes MAW implemented on our hospital retrofit were exceptional. By identifying and resolving potential issues before construction began, we avoided countless headaches and change orders that typically plague complex renovation projects. The accuracy of the point cloud to BIM conversion gave us complete confidence in our design decisions."

Related Services

Ensure Your Project's Success

Ready to reduce errors and minimize risk in your next project? Contact us today to discuss how our error reduction approaches can help ensure your project runs smoothly from design through construction.